This article explains what is Barcode technology? Why Barcode technology is widely used in industries and what are the pros n cons? With the fast changing scene of science and technology, the requirement of computerized input technology is ever increasing.

Various Input Technologies

- OCR(Optical Character Recognition)

- MICR (Magnetic Ink Character Recognition)

- Magnetic cards

- RFID

- Smartcards

- Barcode

There are many input methods in the markets. The traditional method is to use keyboard typing. But it is not sufficient as a mean of item input. The problem associated with manual typing is that the error rate is very high, approximately 1 error per 300 characters. To resolve this problem many automatic input method has been proposed and deployed.

Optical Character Recognition (OCR)

In 1970s, ANSI proposed the OCR standards to be used to label products or documents. OCR is a stylized font recognizable by both human and computers. The problem with OCR is that the Error rate is still too high to be used in major industries. Sample OCR-A, OCR-B Font:

Magnetic ink character recognition (MICR)

MICR characters can be read optically and magnetically because it is printed with a magnetic ink. Currently banking industry is the only one using MICR technology. Since special ink is required, the MICR is expensive for most industries. Sample of MICR font:

Magnetic Cards

Card with magnetic stripes is magnetic card. Now a days magnetic cards like ATM cards, credit cards, debit cards, ID cards, etc are familiar with everyone. The main problem with magnetic cards is– they carry a very little amount of data w.r.t their cost.

Radio Frequency Identification (RFID)

Pioneered by Charles Walton in the late seventies, Radio Frequency Identification (RFID) systems use radio frequency to identify, locate and track people, assets, and animals. The RF reader transmits the commands to the tag, and the tag responds with a radio frequency which stores the information. The benefit of RF technology is that the signal can pass certain distance, easy to communicate with host computers. This technology is most advanced, but yet expensive to adopt.

Smart Cards (IC card)

A smart card is a small package containing circuits and memory chips. It can store and encrypt a lot of information. The cost is relatively high. Subscriber Identity Modules (SIM) used in the network operations of wireless communications operations is the most common example.This article explains what is Barcode technology? Why Barcode technology is widely used in industries and what are the pros n cons? With the fast changing scene of science and technology, the requirement of computerized input technology is ever increasing.

Bar code

Barcode is a machine-readable representation of information in a visual format on a surface. Earlier barcodes stored data in the widths and spacing of printed parallel lines, but today they also come in patterns of dots, concentric circles, and hidden images. The substantial advantages of barcode technology are very low printing cost and error rates. The Standard Error Rate (SER) is usually 1 per 1 million characters and FRR is usually higher than 90%. Due to this reason, barcode technology is now widely used in most of industries as a means of automatic input.

Points of discussion

- History

- Barcode System

- Working procedure

- Symbology

- Types of Barcodes

- Applications

- Advantages and Disadvantages

History of Barcode

The idea for the barcode was developed by Norman Joseph Woodland and Bernard Silver. In 1948 they were graduate students at Drexel University. They developed the idea after hearing the president of a food sales company wishing to be able to automate the checkout process.

The first bar code reader was built by Woodland and Silver in 1952 and included a 500 watt light bulb and a photomultiplier vacuum tube. Woodland at IBM developed the linear barcode that was adopted on April 3, 1973 as Universal Product Code. On June 26, 1974, the first retail product (a 10 pack of Wrigley’s Juicy Fruit chewing gum) was sold using a barcode reader, at Marsh's supermarket in Troy, Ohio. (This pack of gum is now in the Smithsonian's Museum of American History.)

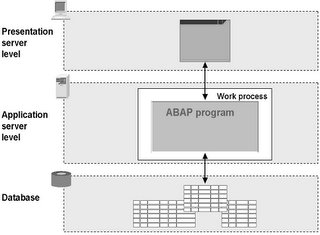

Barcode system

A Barcode system consists of the following components:

- Scanners

- Printers

- Barcode utility software

- Processing Node

Scanners- A barcode reader (or scanner) is a computer peripheral for reading barcodes printed on various surfaces. There are many type of scanners available in the market, which are as following- Wand scanners, CCD scanners, Laser scanners, Image scanners, High density scanners, Long range scanners, Omni directional scanners, 2-D scanners.

Printers- A Barcode Printer is a device to produce labels printed with Barcodes. Mainly two types of printing technologies are being used these days. These are Thermal Transfer printing and Direct Thermal (ribbon less) printing.

Barcode Utility Software– The Barcode utility software is a package of software, which is responsible for generating the Barcode’s patterns according to the collected data.

Processing node– Processing node deals with coordination and working of all the components stated above. A computer system is used as a processing node.

Working Procedure

The unit of measurement of a Barcode is the width of the narrowest bar, measured in mils or 1/1000 of an inch. A 15 Mill barcode, for instance, has a narrow bar that is 15/1000 inches wide.

Reading a Barcode is a 3-step process:

- Scanning

- Decoding

- Processing and Analysis

The process begins when a device (barcode reader) directs a light beam through a bar code. The device contains a small sensory reading element. This sensor detects the light being reflected back from the bar code, and converts light energy into electrical energy.Step two involves converting the electrical signal into data, which is accomplished with a decoder. A decoder may be located inside or outside the input device (i.e. Barcode reader). The decoder is an electrical device serving three functions:

1. It discriminates between the various barcode types, known as symbologies.

2. It decodes the electrical signal into information.

3. It translates the information into data for the host.

Finally, the translated data is inputted into the host computer system, where further processing and analysis is done.

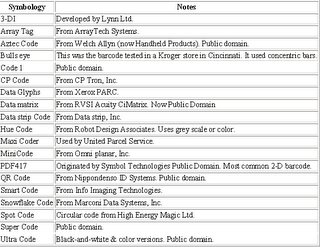

Symbologies

If we look closely, we undoubtedly notice that not all bar codes are same. Some have several different widths of black bars; some are longer or taller while others are more compressed and shorter. In fact, there are over 100 different bar code symbologies. The mapping between messages and barcodes is called a symbology.

The spaces and bars of a bar code are a simplified language in the manner that COBOL, BASIC and FORTRAN are simplified languages which allow programmers to speak with computers. Bar codes look "strange" because the bars and spaces are the elements of a language which can be easily understood by a computer. In essence, bar code symbologies are a sort of "in-between" language which allows humans and computers to communicate.

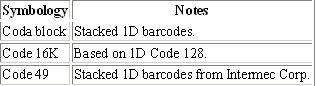

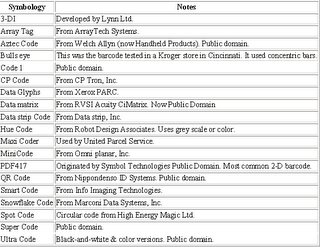

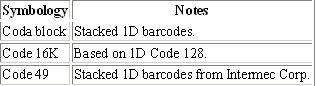

Symbologies can be categorized as the following:

- Linear symbology

- Stacked symbology

- 2-D symbology

Linear symbologies can be classified mainly by two properties- Continuous vs Discrete and Two width vs Many width. Stacked symbologies consist of a given linear symbology repeated vertically in multiple rows.

There are a large variety of 2-D symbologies. The most common are matrix codes, which feature square or dot-shaped modules arranged on a grid pattern. 2-D symbologies also come in a variety of other visual formats. Aside from circular patterns, there are several 2-D symbologies which employ steganography by hiding an array of different-sized or -shaped modules within a user-specified image (for example, DataGlyph).

Linear symbologies are optimized to be read by a laser scanner, which sweeps a beam of light across the barcode in a straight line, reading a slice of the barcode light-dark patterns.

Stacked symbologies are also optimized for laser scanning, with the laser making multiple passes across the barcode.

2-D symbologies cannot be read by a laser as there is typically no sweep pattern that can encompass the entire symbol. They must be scanned by a camera capture device.

Types of barcodes

Linear barcodes

Stacked barcodes

2-D barcodes

Applications

Barcodes are used wherever physical objects need to be tagged with information that is to be processed by computers. They also work well in fully automated environments, such as baggage routing at airports.

The EAN-13 and UPC codes commonly found on retail articles work this way. A popular application of Barcode is tagging of books, where EAN-13 and Bookland are used. Barcodes are extensively being used in PostOffices, bloodbanks, nearly all retail articles, electronic goods, air baggages and bills.

Illustration of some popular barcodes:

Advantages and Disadvantages

Speed: A bar code label of twelve characters can be wended in approximately the time it takes a keyboard operator to make two keystrokes.

Accuracy: For every 1,000 characters typed by a keyboard operator, there is an average of ten keying errors. For an Optical Character Reader (OCR), there is one error in every 10,000 reads. A bar coding system approach one error in every 3,000,000 characters and with laser technology, they approach one error in 70 million entries.

Data integrity: Probable number of substitution errors for every 3,400,000 characters entered:

Keyboard Entry : 10,000

OCR Scanning : 300

Bar Coding (Code 39): 1

Ease of implementation: Operators of bar code scanners can learn to use the equipment effectively in less than 15 minutes. System costs are lower than other means of data entry because of the existence of interfacing hardware and software.

Cost effectiveness: Bar coding has a demonstrated payback period of six to eighteen months. In short, bar coding has the proven highest level of reliability. Bar coding equipment are less expensive in comparison to other techniques. Bar code labels can be used in harsh environments where there are extreme temperatures and dirt.

Limitation: Unlike RFID system barcode system is very much limited to a certain distance. Barcode systems can’t be operated for long distance operations like shipyard container tagging, wildlife tagging, etc.